With the advent of Industry 4.0 and the era of intelligent manufacturing, automated production lines have become one of the core technologies in modern manufacturing. By integrating advanced automation equipment, control systems, and information technology, automated production lines can achieve efficient, precise, and flexible production operations. This article will delve into the characteristics and advantages of automated production lines and analyze their profound impact on the development of the manufacturing industry.

Characteristics of Automated Production Lines

1. High Efficiency: Automated production lines optimize the production process and equipment configuration to achieve continuous and high - speed production operations, significantly improving production efficiency.

2. Precision: Equipped with high - precision sensors and control systems, automated production lines can precisely control every production step, ensuring the stability and consistency of product quality.

3. Flexibility: Modern automated production lines are highly adjustable and adaptable, capable of rapid adjustment and switching according to different products and market demands.

4. Intelligence: Automated production lines widely apply Internet of Things (IoT), big data, and artificial intelligence (AI) technologies to achieve intelligent monitoring, data analysis, and production optimization.

5. Safety: Automated production lines are equipped with various safety protection devices and systems, effectively reducing safety hazards during production and ensuring the safety of operators.

Main Advantages of Automated Production Lines

1. Improved Production Efficiency: Automated production lines significantly enhance production efficiency by reducing manual operations and optimizing the production process. Traditional manual production methods often require a large amount of manual labor and frequent adjustments, while automated production lines can achieve continuous and high - speed production operations, reducing waiting time and downtime during production. For example, in the automotive manufacturing industry, automated production lines can assemble a large number of components in a short time, greatly increasing production speed and efficiency.

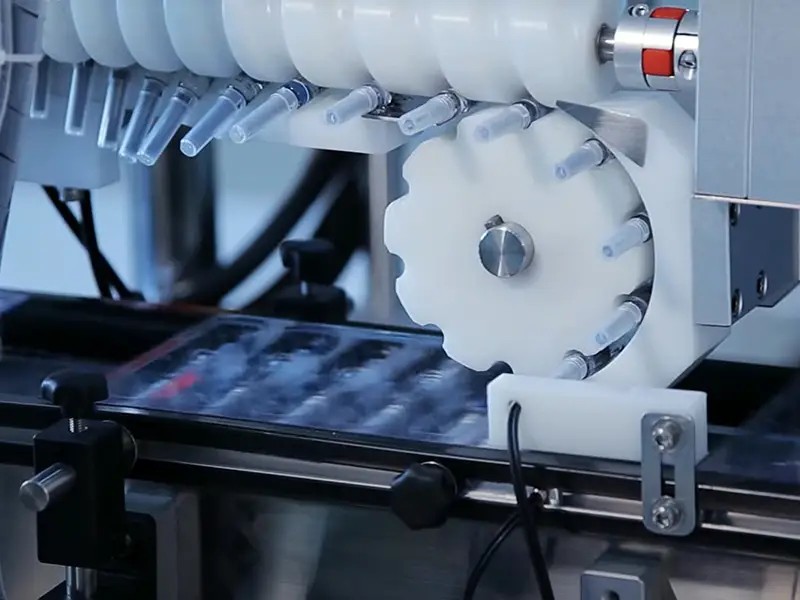

2. Enhanced Product Quality: Automated production lines are equipped with advanced sensors and control systems that can monitor and control every production step in real - time, ensuring the consistency and stability of product quality. The high - precision operations of automated equipment reduce human errors and improve product precision and consistency. For example, in the electronics manufacturing industry, automated production lines can precisely control every soldering point and assembly step, ensuring that each product meets high - quality standards.

3. Reduced Production Costs: Although the initial investment in automated production lines is relatively high, their high - efficiency production capabilities and low operating costs significantly reduce overall production costs. Automated production lines reduce dependence on manual labor, lowering labor and management costs. In addition, efficient production and precise control reduce raw material waste and improve resource utilization. For example, in the food processing industry, automated production lines can precisely control the amount of raw materials used, reducing waste and lowering production costs.

4. Increased Production Flexibility: Modern automated production lines are highly flexible and can be quickly adjusted and switched according to different product requirements. By changing molds, adjusting parameters, and upgrading software, automated production lines can meet the production needs of products of various specifications and shapes, satisfying the diverse demands of the market and enhancing the market competitiveness of enterprises. For example, in the home appliance manufacturing industry, automated production lines can quickly adjust production parameters to meet the production needs of different models of home appliances.

5. Improved Operational Safety: The use of automated production lines reduces the frequency and intensity of manual operations, lowering the risk of safety accidents during operation. Equipment is usually equipped with various safety protection devices, such as safety doors, emergency stop buttons, and photoelectric protection, to ensure the safety of operators. In addition, automated operations reduce the labor intensity of workers and improve the safety and comfort of the working environment. For example, in the chemical production industry, automated production lines can automatically handle and operate hazardous chemicals, reducing the risk of workers coming into direct contact with dangerous substances.

6. Data Monitoring and Management: Automated production lines are equipped with advanced data collection and monitoring systems that can monitor various data during the production process in real - time, record, and analyze it. Enterprises can use this data to optimize and improve the production process, enhancing production efficiency and product quality. At the same time, the accumulation and analysis of data can also provide a scientific basis for enterprises' production decisions, promoting the intelligent management of enterprises. For example, in the pharmaceutical industry, automated production lines can record the production data of each batch of drugs in real - time, facilitating tracking and management, and improving the transparency and safety of drug production.

Development Directions of Automated Production Lines

1. Intelligence and Digitalization: With the development of Industry 4.0, automated production lines will become more intelligent and digital. By introducing Internet of Things (IoT) and artificial intelligence (AI) technologies, equipment can achieve intelligent monitoring, predictive maintenance, and production optimization, improving the intelligence level of equipment.

2. Modular Design: Future automated production lines will be more modular, enabling rapid adjustment and upgrading according to different production needs, and improving the flexibility and production efficiency of equipment.

3. Environmental Protection and Energy Conservation: Environmental protection and energy conservation will become important development directions for future automated production lines. Equipment will use more environmentally friendly materials and energy - saving technologies to reduce energy consumption and environmental pollution, promoting the development of green manufacturing.

4. High Precision and High - Speed: As the market's demand for high - quality and high - efficiency products continues to increase, automated production lines will develop towards higher precision and higher speed, enhancing production efficiency and product quality.

5. Human - Robot Collaboration and Safety: Collaborative robots will be widely used in automated production lines. Combining artificial intelligence and sensing technologies, human - robot collaborative equipment will achieve more efficient and safer production operations, improving production efficiency and the safety of the working environment.

Automated production lines, with their high - efficiency, precision, and stability, are leading the development trend of modern manufacturing. They have significant advantages in improving production efficiency, enhancing product quality, reducing production costs, increasing production flexibility, improving operational safety, and data monitoring and management, and have become an important means for enterprises to enhance their market competitiveness. With the continuous progress of technologies such as intelligence, digitalization, modularization, environmental protection, and human - robot collaboration, automated production lines will continue to develop, bringing greater economic benefits and market competitiveness to enterprises. In the future, automated production lines will continue to play an important role, promoting various industries towards high - efficiency, intelligent, and sustainable development.