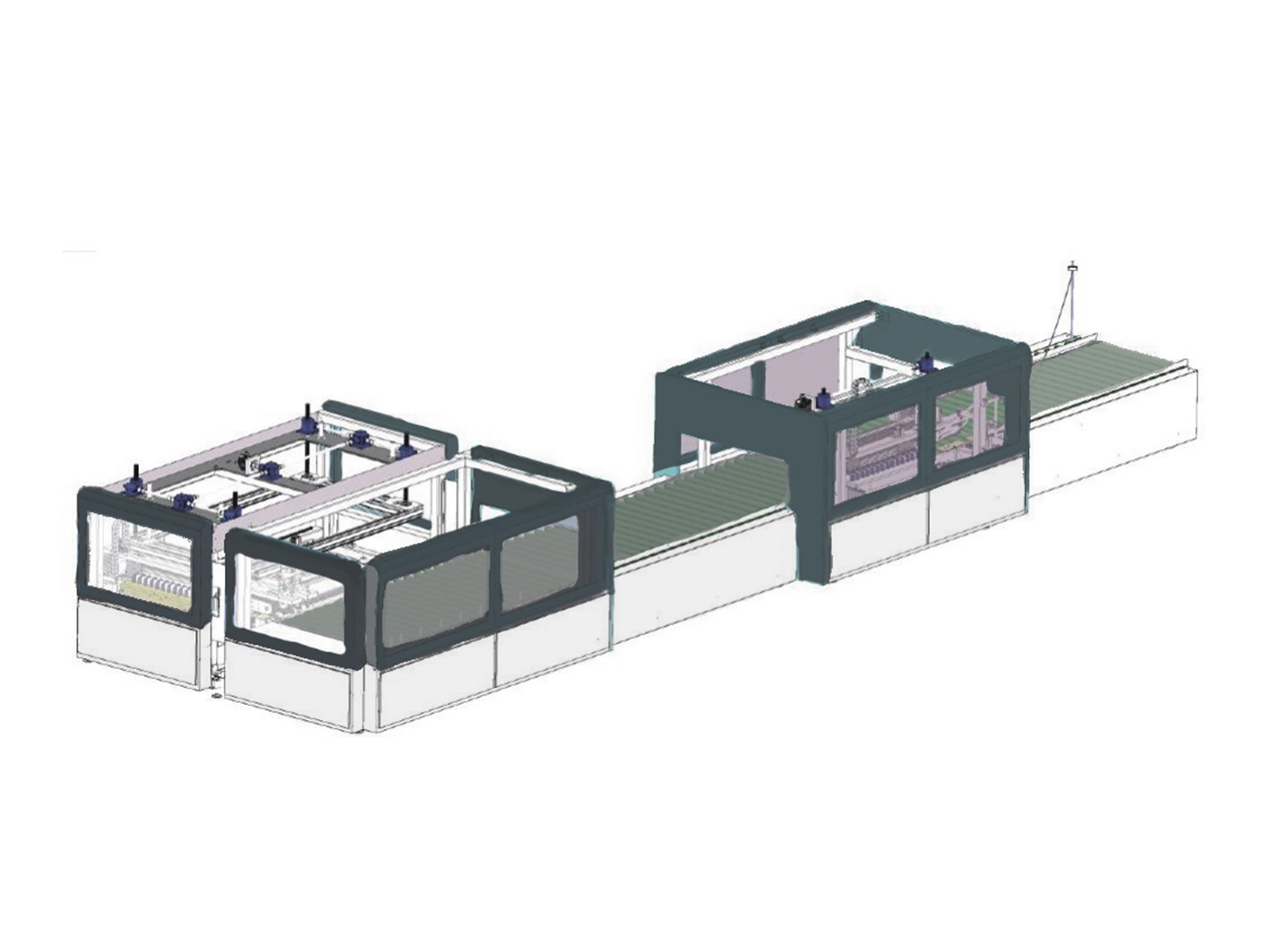

An automatic door panel packaging line is an advanced system designed to enhance the efficiency and effectiveness of packaging door panels, primarily in manufacturing and distribution settings. Our fully automatic packaging equipment can efficiently and precisely complete the packaging process for flooring products.

The fully automated packaging solution for flooring is widely used in the automatic packaging segment for flooring and is commonly employed in leading flooring factories abroad.

Through deeply customized automation solutions, it effectively addresses production challenges such as low-value labor, high-intensity operations, and hazardous tasks.

These systems integrate multiple components-including infeeding and outfeeding conveyors, wrapping machines, film covering machines, and control systems-to automate the packaging process, thereby improving throughput and reducing labor costs. This automation allows for precise, consistent packaging that meets the demands of modern production environments, ensuring products are well-protected for shipping while minimizing handling times.

As industries increasingly embrace automation, these systems play a crucial role in maintaining high production rates and improving overall operational efficiency.

Specification

|

Spec |

total weight |

speed |

ARIS |

||

|

length |

Width |

Height |

About 7T |

8-12 pcs/min |

0.6Mpa |

|

300-2400mn |

200-900mm |

30-200mm |

|||

|

Spec |

|

|

Rack |

100*150(100) rectangular bridge pipe CNC machining |

|

Precision roller |

φ50/ shaft 15, hot-dip galvanizing + non-stick processing |

|

idler wheel |

Full Teflon control processing |

|

hot melt glue machine |

USA NORDS& Spanish MELER |

|

hot melt glue gun |

Super speed point gun |

|

PLC |

Kymmene |

|

Low pressure electricity |

Schneider |

|

Synchronous lift linkage |

Worm gear connecting rod synchronization |

|

High precision coaxial drive |

Hexagon shaft + copper flange coaxial synchronous drive |

Features

Safety Features

To ensure safe operation, the packaging line includes various safety features such as an emergency stop function and sensor-based safety systems that detect obstacles or malfunctions. These measures are vital for preventing accidents and protecting operators.

Energy Efficiency Features

Modern automatic door panel packaging lines are designed with energy-saving modes and eco-friendly options, reducing long-term energy costs while maintaining high output levels. These features appeal to companies focused on sustainability by allowing the use of recyclable packaging materials.

Operation

The operation of an automatic door panel packaging line is a sophisticated process designed to streamline the packaging of door panels, ensuring efficiency and consistency in production. This automated system typically involves several key stages that work in unison to optimize productivity and product quality.

Benefits of Using

- Cost-Effectiveness

- Increased Efficiency and Speed

- Consistent Quality Control

- Enhanced Safety Features

- Sustainability Considerations