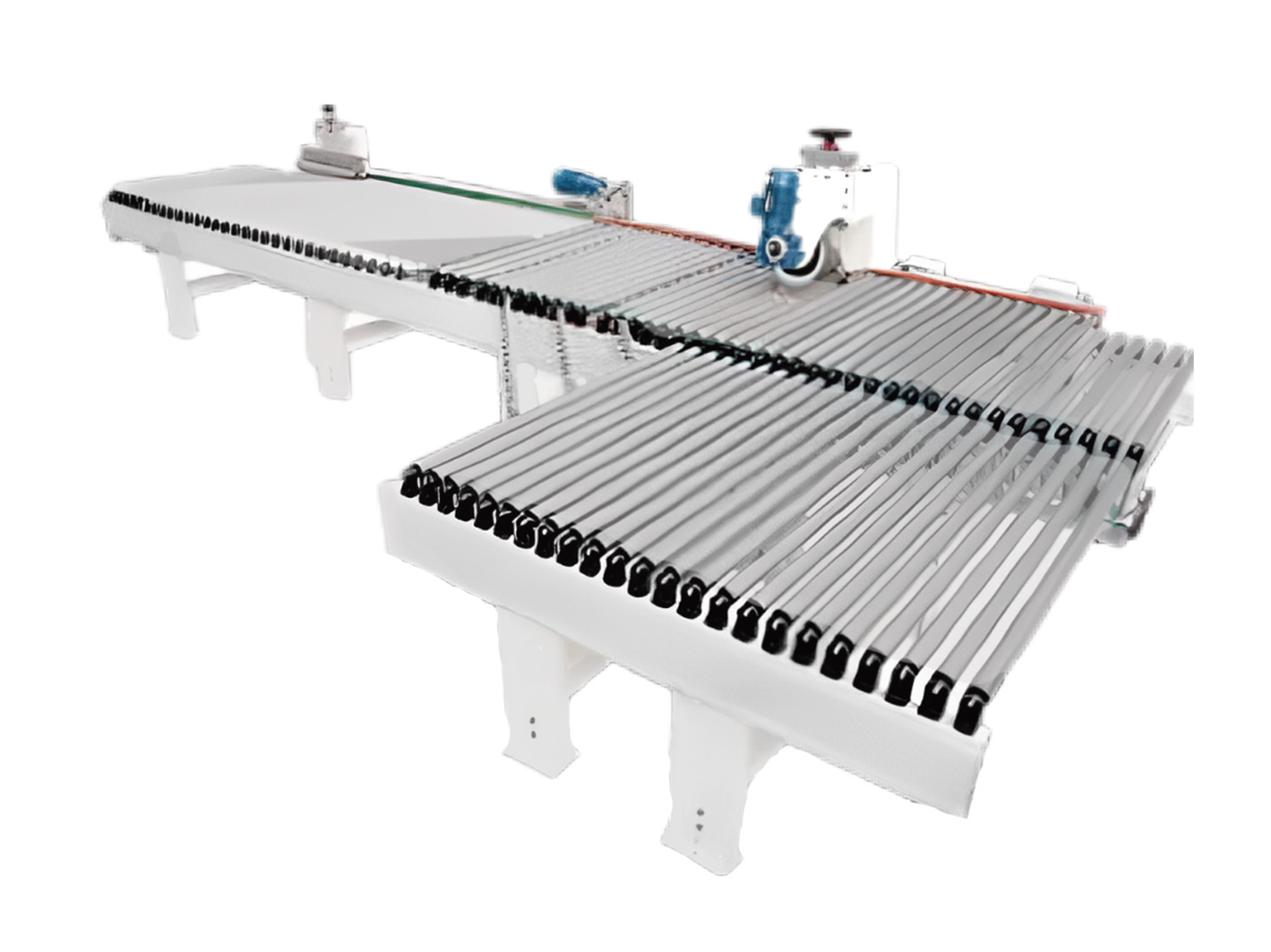

The 90 degree cone-roller type turning machine is equipped with upper and lower conical rollers to clamp the plate. The technical effect of horizontal steering of the plate is realized by using the linear speed difference of the conical part with large and small diameter of the conical roller, so as to improve the smooth steering ability of the plate and reduce the damage to the plate.

The 90 Degree Cone-roller Type Turning Machine is a specialized CNC (Computer Numerical Control) device designed for the precise machining of conical shapes and complex geometries. With our professional technical and IT team, we can customize for your different factory requirements.

Notable for its unique configuration, 90 Degree Cone-roller Type Turning Machine enhances efficiency and accuracy in the manufacturing process, making it invaluable in industries such as furniture,automotive, and new energy, where high precision is paramount.

Features

|

Technical Data |

BST-ZN-CLS300*1300*920 |

|

Equipment Size |

5000*2760*920±50mm |

|

Maximum swivel plate size |

2440*1220*60mm |

|

Minimum swivel size |

300*300*10mm |

|

Cycling rate |

Continuous rotation without pause |

|

motor power |

0.75kw,1.5kw,5.5kw |

|

plate cylinder speed |

50M/min |

|

Load |

50kg |

Applications

The 90 Degree Cone-roller Type Turning Machine is widely utilized across various industries.

Manufacturing Components

One of the primary applications of the 90 Degree Cone-roller Type Turning Machine is in the manufacturing of components used in the automotive and aerospace sectors. These industries demand high precision and reliability, making the machine suitable for producing parts like gear cones, hub assemblies, and other conical components that are integral to vehicle and aircraft assemblies.

Tool Path Optimization

The machine excels in optimizing tool paths, which can either be automated by the CAM software or manually created for basic parts. This capability allows for efficient material removal and ensures that the final products meet stringent tolerance requirements.

Hybrid Manufacturing

In recent years, there has been an increasing trend toward hybrid manufacturing, where traditional CNC machining processes are combined with additive manufacturing techniques like 3D printing.

The 90 Degree Cone-roller Type Turning Machine plays a critical role in these setups, allowing for the creation of complex parts that may include both machined and 3D-printed elements, thus optimizing material usage and reducing lead times.

Advantages

The utility model has the advantages of simple structure, convenient operation, simple reversing process, easy control and small space occupation, which can effectively save the plant space and indirectly reduce the production cost.

High precision

One of the primary benefits of 90 degree cone-roller type turning machines is their high precision. These machines are designed to achieve exceptional accuracy, which is crucial for producing components with intricate designs and tight tolerances, especially in industries such as aerospace and medical devices.

High efficiency

The ability to perform multiple machining operations in a single setup reduces the need for part transfers between different machines, thereby streamlining production and significantly decreasing lead times.

Comparison with Other Turning Machines

In comparison to conventional turning machines, the 90 Degree Cone-roller Type Turning Machine provides superior precision and efficiency. While standard lathes may face limitations in shaping complex profiles, the cone-roller design facilitates more intricate workpieces by allowing for angular adjustments that enhance the overall surface finish and dimensional accuracy.