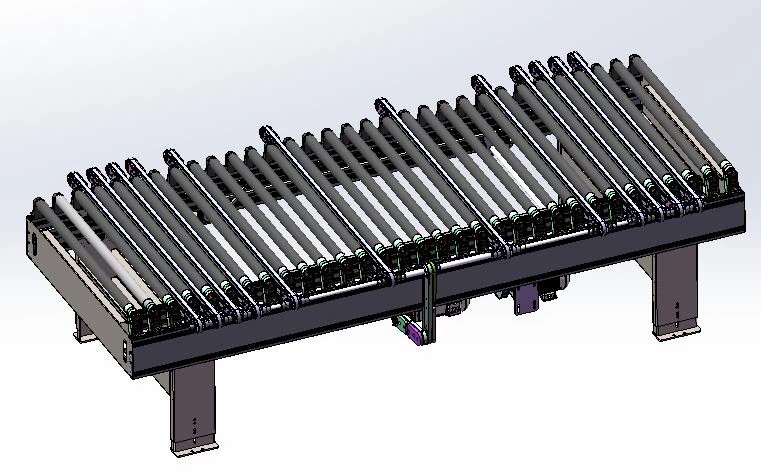

Sorting Roller Conveyor is also a kind of unpowered Roller Conveyor. Unpowered Roller Conveyor, is one of our Beist basic and most fundamental conveyor products . We can say this is the root product of our factory as we have been kept producing it since our opening up, already more than 15 years. We are already more than professional about it.

Difference is this Sorting Roller Conveyor can be used to be a cache splice after connecting with the sorting board, which is usually suitable for matching with the board moving sorting line. And the height can be designed according to the sorting system in your factory.

How does it work?

When the rollers rotate, heavy products can convey through easily, greatly reduce the workload of workers and increase production efficiency. If you have ever been to a large scale production factory, you will feel amazed like me when you see how the rows and lines of unpowered roller conveyor are working silently.

Specification

|

Hard Spec |

|

|

Application condition |

Suitable for sorting to order board |

|

Load |

150kg/m |

|

Drum center distance |

65mm |

|

Drum mounting system |

internal thread |

|

Drive mode |

manual |

|

Girder |

150*40*3mm The thick pickling plate is made by bending and spraying |

|

Barrel |

φ50*1.55mm Hot-dip galvanized pipe sleeve 2mm rubber hose |

|

Inner spindle |

φ12mm Drawing Steel |

|

Stand bar |

3mm Pickling plate bending welding spray |

|

Adjusting leg |

M20*150mm With M8 expansion screw hole |

|

Other |

The last roller can be adjusted up and down separately |

Features

Every Beist conveyor is custom-designed to meet customers' specific needs. We start by understanding our clients' requirements, including the types of products to be handled, the dimensions, and their throughput goals. On basis of this information, we tailor conveyor solutions that align perfectly with our customer's operational demands, ensuring a cost-effective and efficient material handling solution.

Low noise, high efficiency

Reliable and stable, with low operating noise, ensuring a smoother workflow, largely enhancing the transfer efficiency between different producing procedures.

Durable and reliable

Material is mainly made by galvanized sheet, while rollers are made of high-quality wear-resistant and corrosion-resistant finishes reduce friction, passed 72 hour's salt spray test.

Maintenance-Free and long lift span

Good quality rubber hose are added on the rollers except its original surface to protect appearance.

The main beam is bent by the most advanced CNC bending machine, with accurate angle and neat surface;Roller holes are one time processed by CNC Laser Cutting Machine to ensure levelness of the roller surface to and center distance. Basically no maintenance, service life of more than 10 years.

Suggestion

What should you consider for choosing the right roller conveyor?

First, dimensions (length, width, height) and weight of your products. Second, size of the facility.

Thirdly, your budget, because the price of the conveyor system is based on size, speed, and technology and your application situation.

Except unpowered roller conveyor, we can also design much more complicated conveyor system that needs high technique and unpowered roller Conveyors can use together with.

If you are interested in roller conveyors, our kind sales and outstanding engineers team are always here.