JiangSu Beist Intelligent Equipment Co.,Ltd, who has been in the non-standard industry for more than 10 years, is one of China's leading automation equipment manufacturers. With a team of more than 30 professional mechanical engineers and technicians , we have served 10000+ successful cases for more than 30 various industries.

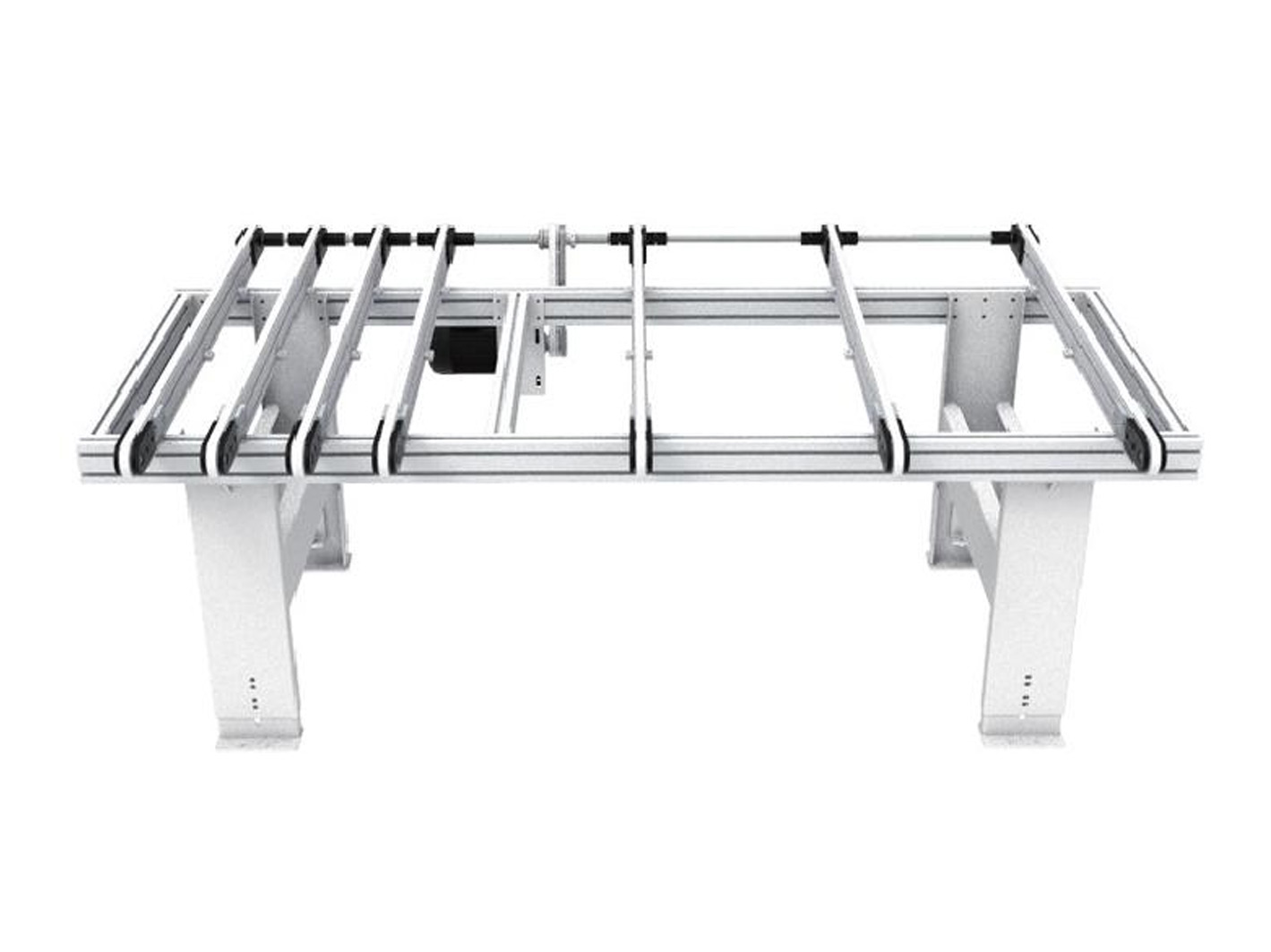

Except powerless series, powered machine is another kind of our Beist main and best selling products. And cross conveyor is one of them.

Cross conveyors are specialized material handling systems designed to transfer goods between different conveyor lines or facilitate directional changes within an industrial process. They play a crucial role in enhancing efficiency across various sectors, including manufacturing, food processing, warehousing, e-commerce, and recycling. By automating the movement of materials, cross conveyors minimize manual handling, reduce bottlenecks, and streamline production workflows by significantly improving operational productivity and safety.

Historically, the development of conveyor systems has transformed industrial operations since the early 20th century, with cross conveyors emerging as vital components of modern manufacturing and logistics. Their evolution has been driven by technological advancements, such as the integration of the Internet of Things (IoT) and artificial intelligence (AI), which enable real-time monitoring and predictive analytics to enhance efficiency and accuracy.

Additionally, these systems contribute to environmental sustainability by optimizing resource usage and minimizing waste in various operations.

Features

|

Model |

Width(mm) |

length(mm) |

Height(mm) |

|

20201 |

1300 1660 |

2800 3000 3300 |

725±50 825±50 925±50 |

|

Item |

Specification |

|

Application |

Single sheet or package for delivery |

|

Load |

60kg/set |

|

Speed |

0-33m,45m,65m,108m/m adjustable |

|

Power |

0.75kw,1.5kw |

|

Stand bar |

The 5mm thick pickling plate is bent |

|

Girder |

100*50mm aluminum profile |

|

Synchronous no |

According to the length of the workpiece design, the conventional 7 groups, 8 groups |

|

Whether to bring over the wheel |

□No □Yes |

Applications

Overview of Cross Conveyors

Cross conveyors play a pivotal role in material handling systems across various industries by facilitating the efficient transfer of goods between different production lines or processing areas. These systems are particularly beneficial in settings where space optimization and quick product movement are essential for maintaining operational efficiency.

Industrial Manufacturing

In industrial manufacturing, cross conveyors are often employed to transport components or finished products between different stages of production. For example, in automotive manufacturing, cross conveyors can help streamline assembly line processes by transferring parts from one line to another, thereby reducing bottlenecks and enhancing overall productivity.

Food Processing

The food processing industry heavily relies on cross conveyors to maintain high standards of hygiene and efficiency. Custom-designed cross conveyor systems can be integrated with sanitation features to prevent contamination and ensure compliance with regulatory requirements.

Warehousing and Distribution

In warehousing and distribution centers, cross conveyors are essential for optimizing storage capacity and maximizing throughput. These systems facilitate the rapid movement of goods, enabling efficient sorting and retrieval processes.

For example, a distribution center may utilize cross conveyors to transport products from bulk storage areas to picking zones, significantly reducing the time taken to fulfill orders. This capability is especially valuable in environments where speed and accuracy are critical for meeting customer demands.

Advantages

Cross conveyors offer a multitude of advantages that enhance material handling efficiency across various industrial applications. Their integration into production processes has proven to be a game-changer, particularly in high-volume environments.

Improved Safety

Safety is a paramount concern in industrial environments, and cross conveyors contribute to a safer workplace by reducing the need for manual handling of heavy loads. Their robust construction and safety features help mitigate the risks associated with transporting goods, thereby improving overall workplace safety standards.

By minimizing the physical strain on workers and decreasing the likelihood of accidents, cross conveyors foster a more secure operational environment.

Enhanced Efficiency and Speed

One of the primary benefits of cross conveyors is their ability to significantly increase operational efficiency. By automating the movement of products, they streamline workflows and minimize the time spent on manual handling. This efficiency is crucial for industries such as food processing and automotive manufacturing, where speed and accuracy directly impact productivity levels.

The use of cross conveyors allows for faster processing times, reducing cycle duration and increasing overall output.

If you are interested in our conveyors, please feel free to consult us, our professional team will give you a one stop solution to solve your current problem in your factory with our professional team and greatest sincerity.