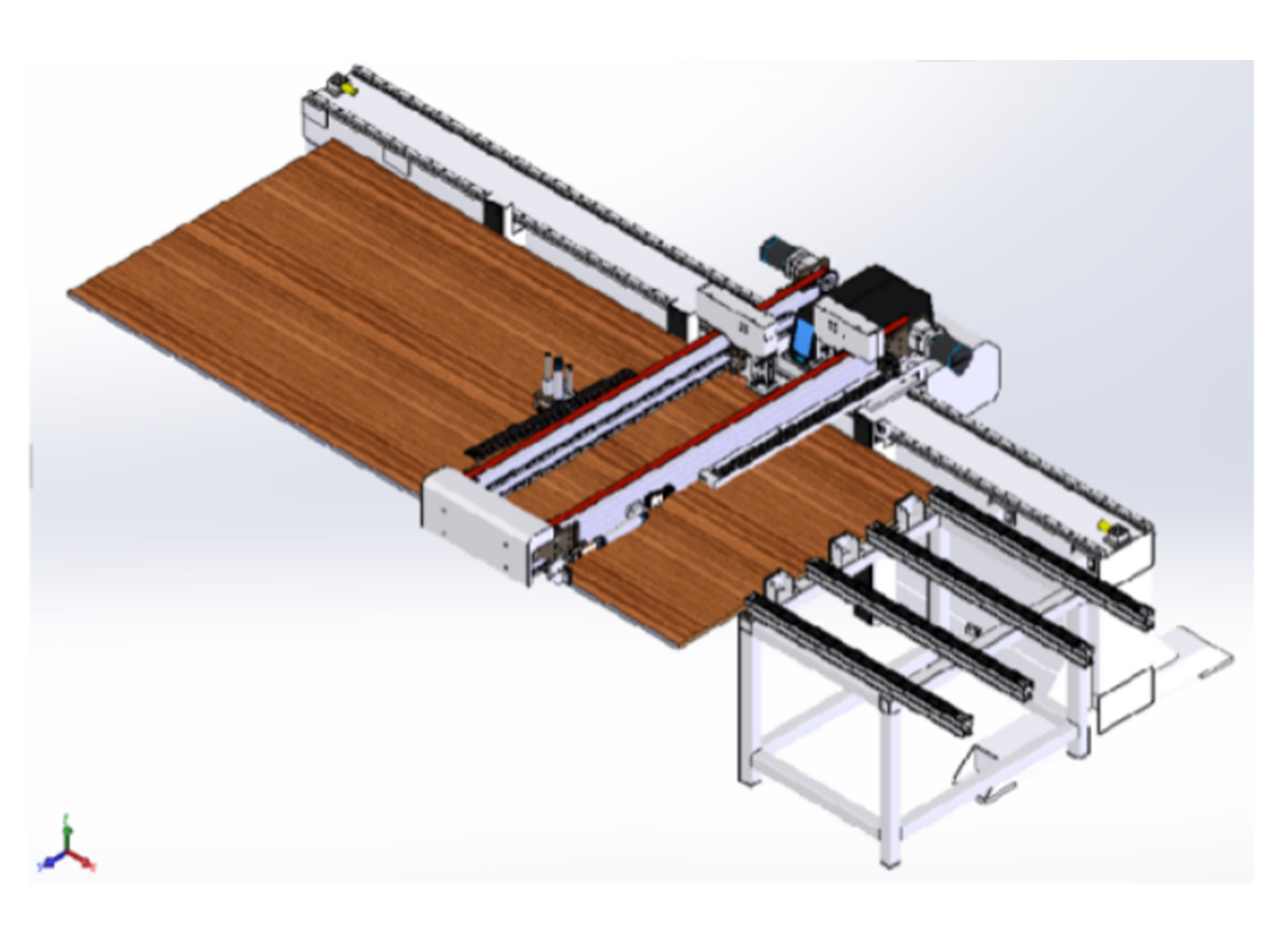

Single-arm panel over-turner is also a kind of powered roller conveyors.

The difference with Automatic flip machine is its over-turner direction.

Single-arm panel over-turner is a type of automated machinery designed to flip or reorient products during manufacturing processes, significantly enhancing efficiency and precision in various industries.

Due to its ability to streamline production lines, reduce labor costs, and improve product quality, thereby addressing the increasing demands for rapid and flexible manufacturing solutions in a competitive market, so nowadays, they become more and more popular among the market.

Specification

|

Item |

Specification |

|

Equipment Size |

3000*3000*920mm |

|

Maximum over turn size |

2440*1220*24mm |

|

Minimum over turn size |

2400*200*10mm |

|

Over turn speed |

2 times /min |

|

Motor power |

5.5kw |

|

cylinder speed |

50m/min |

|

load |

100kg |

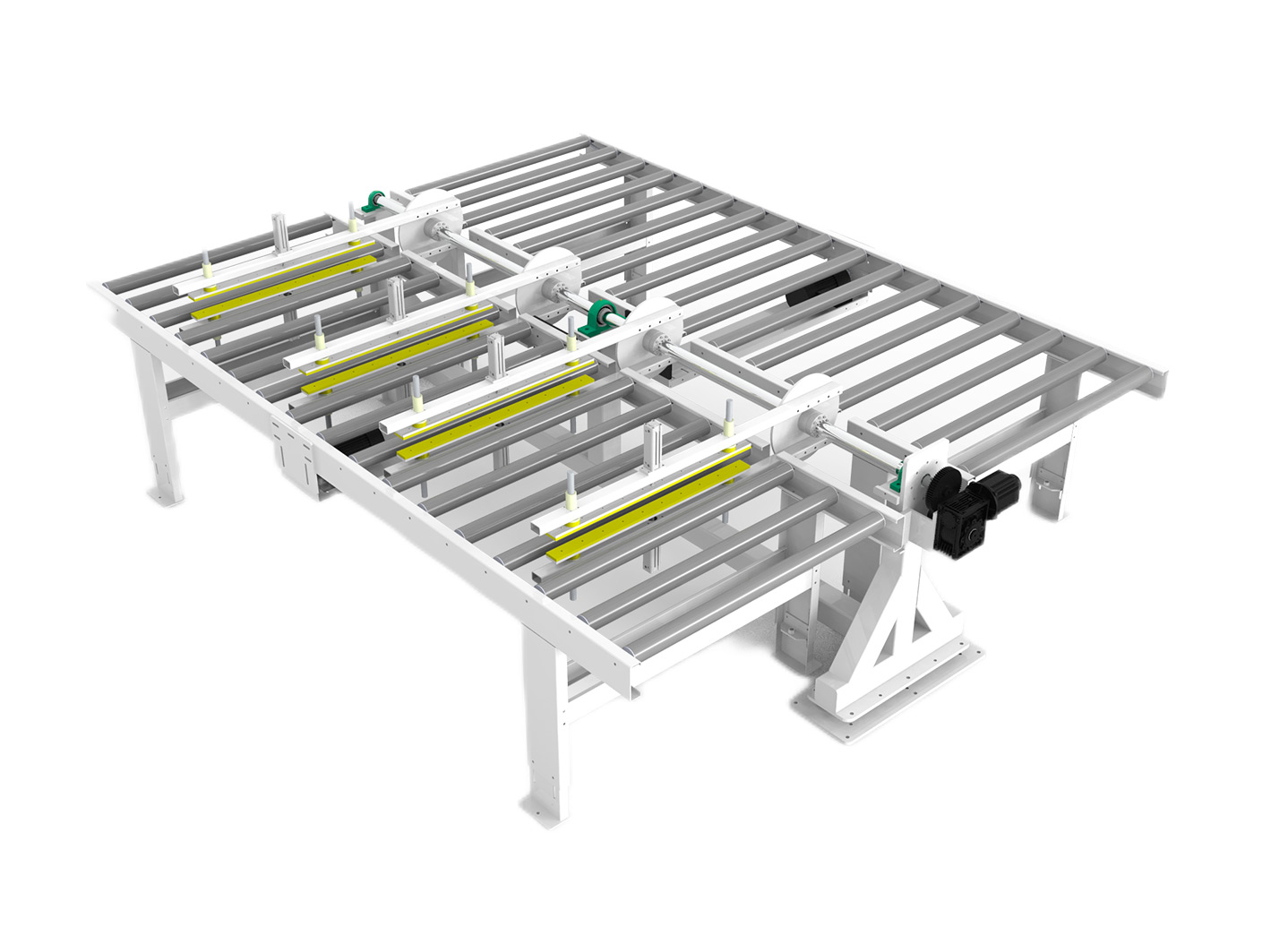

Features

- Load ≤100kg

- Working by the elastic belt,noise is very small.

- Girder is made of Aluminum, weight is light.

- Continuous flip, no need return to zero. High Efficiency.

- Flip integrated welding, strong stability.

- Automatic flap, will reduce the plate surface scratch, reduce the defective rate.

- Suitable for UV rotating line, one drag three, one drag four, docking two lines, etc.

How to choose a Single-arm panel over-turner?

- Single-Arm Mechanism

- Rotation Control: Programmable rotation (90°, 180°, or custom angles) or (motors hydraulic/pneumatic actuators)

- Load Capacity

- Safety Sensors

Advantages

A single-arm panel over-turner is specially designed for material handling designed to flip or rotate large panels (e.g., metal, or composite sheets) during manufacturing, assembly, or packaging processes.