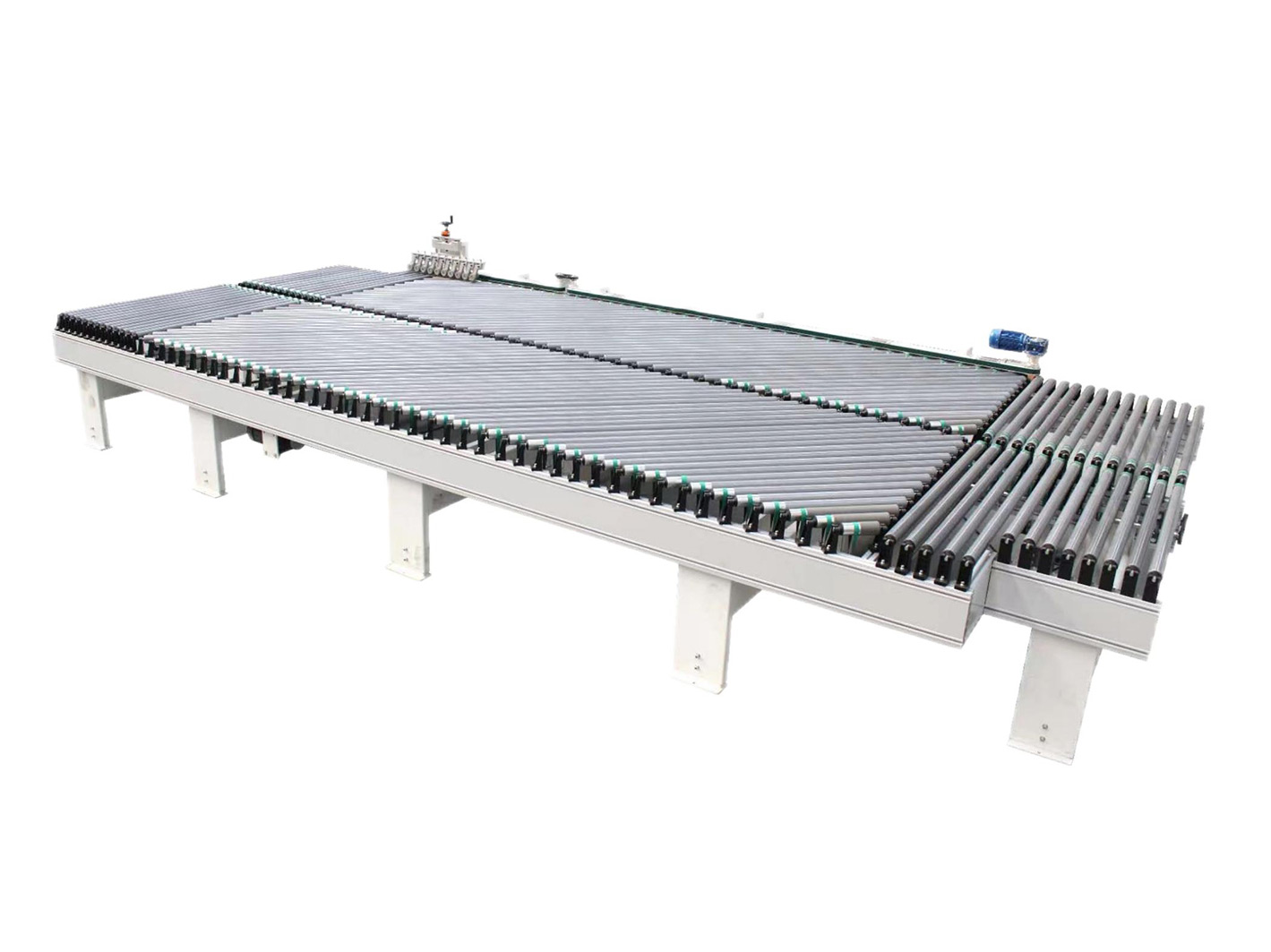

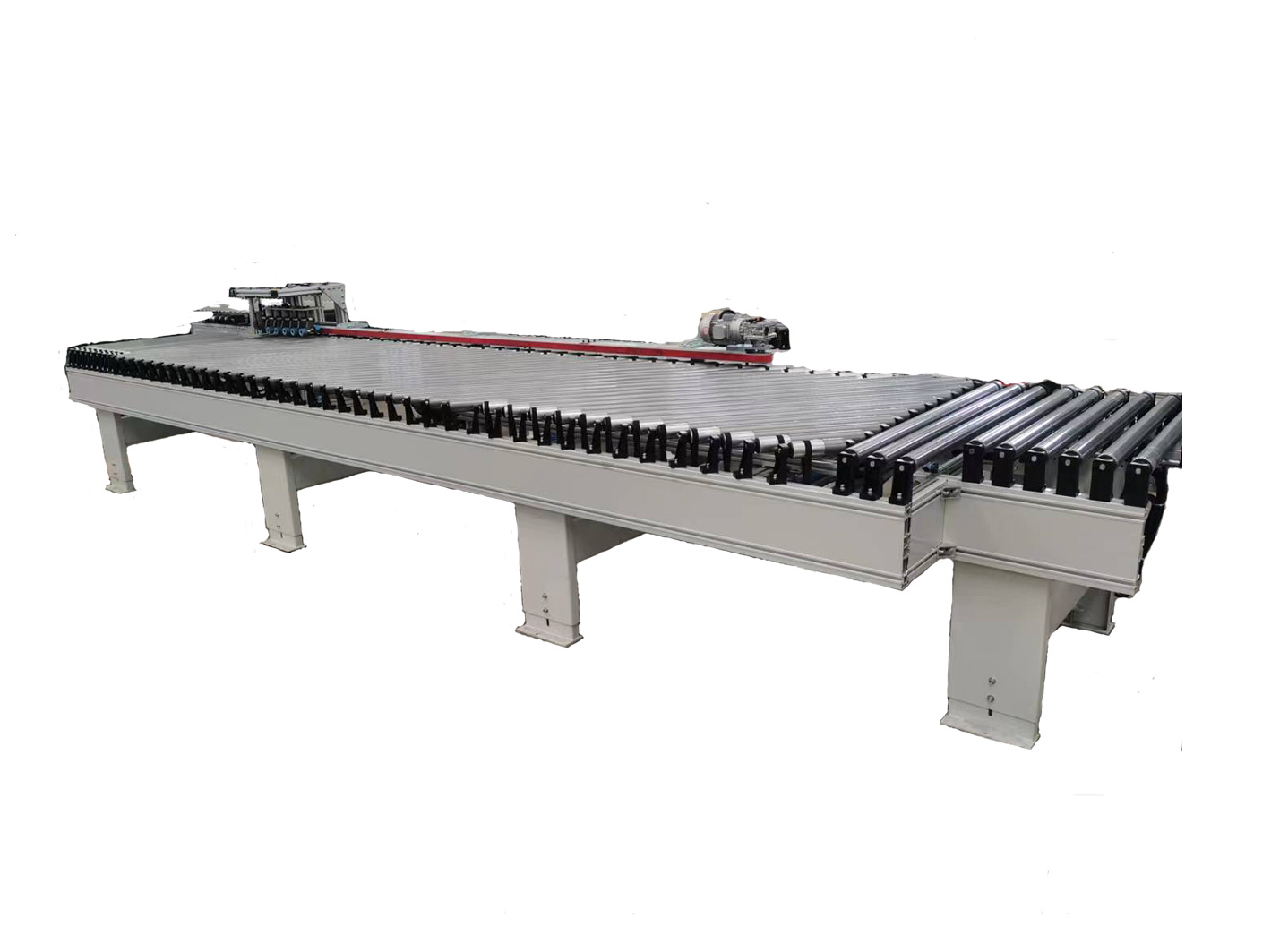

Equipment Size: 8100*2700*920mm<br /><br />

Delivery Workpiece Length: 250-2800mm<br /><br />

Transfer Workpiece Width: 250-1220mm<br /><br />

Short and Short Sides Ratio of Workpiece: 6:1<br /><br />

Equipment Speed: 50m/min<br /><br />

Motor Power: 3.5KW<br /><br />

Load: 50kg

BEIST's return conveyor for edge banders (roller conveyor) is specially designed for the automated edge banding and conveying of wood boards, sheets, and furniture parts, enabling the unmanned operation of the entire process: loading → edge banding → unloading. It adopts a servo drive and intelligent control system to accurately handle boards of different specifications (length: 250–2800mm), helping enterprises improve production efficiency and reduce labor costs. It is a core intelligent equipment for furniture manufacturing and building materials processing.

Our roller conveyor for edge banders automates the return of finished workpieces to the operator's station, minimizing manual handling and streamlining manufacturing workflows. It enables quick transitions between production tasks, adapting to diverse materials and demands without extensive retooling. This adaptability is vital for manufacturers aiming to stay competitive in dynamic markets where rapid order fulfillment is critical.

Jiangsu Beist Intelligent Equipment Co., Ltd. has focused on industrial automation for over 15 years, providing non-standard customization, system integration, and global one-stop after-sales services. It has delivered reliable solutions to more than 100 companies worldwide.

Core Features of Roller Conveyor For Edge Bander

Efficient Collaboration and Seamless Integration

* Left and right manipulator coordination: Automatically grabs, flips, and positions workpieces, reducing labor by 3-4 workers and boosting efficiency by 30%.

* Roller conveyor: Speed adjustable from 0–50 m/min, suitable for high-speed edge banding machines.

High-Precision Intelligent Control

* Servo motor with encoder: Achieves positioning accuracy of ±0.5mm, eliminating plate offset.

* PLC-HMI interface: Pre-programmed with 100+ recipes for one-click switching between different plate specifications.

Sturdy, Durable, and Easy to Maintain

* Galvanized steel roller: Load capacity of 50kg/m, wear-resistant, and rust-proof.

* Modular design: Features a quick-disassembly structure, enabling cleaning and maintenance in just 15 minutes.

Safety Protection

* Photoelectric sensor and emergency stop button: Automatically decelerates when people approach, complying with CE safety standards.

* Anti-collision buffer device: Prevents damage to stacked plates from collisions.

Specification - Edge Banding Machine Roller Conveyor

|

Technical Data |

BST-ZN-ZYS 8100*2700*920 |

|

Equipment Size |

8100*2700*920mm |

|

Delivery Workpiece Length |

250-2800mm |

|

Transfer Workpiece Width |

250-1220mm |

|

Short and short sides Ratio of workpiece |

6:1 |

|

Equipment Speed |

50m/min |

|

Motor power |

3.5kw |

|

Load |

50kg |

Applications of Left-Right Slanting Line For 2 Edge Banders

Furniture Manufacturing

Return conveyor systems play a key role in furniture manufacturing. Edge banding machines automate the finishing of furniture panels, optimizing production workflows.

Cabinetry Production

Return conveyor systems optimize edge-banding operations in cabinetry production. They automate material handling by seamlessly guiding panels back to the edge bander for subsequent processing.

Interior Finishes and Paneling

Return conveyor systems are ideal for producing interior finishes and paneling. Their ability to efficiently edge-band large panels makes them particularly valuable for these applications.

Advantages

- Improved Efficiency and Productivity

- Cost Savings

- Flexibility and Adaptability

- Enhanced Quality and Reduced Damage

- Long-term Sustainability

Packaging and delivery

Shockproof Packaging: Pearl cotton and a customized iron frame, resistant to impacts and bumps.

Sea Transportation Protection: A fixed frame is installed in the container to adapt to marine transportation conditions.

Export Certification: CE and ISO 9001 certified, approved for markets in Southeast Asia, the Middle East, Europe, and the United States.

After-sales Guarantee: 48-hour fault response time.

Why Choose BEIST?

One-stop Customized Service

From demand analysis to solution design, production commissioning, and after-sales support – a hassle-free process from start to finish!

Non-standard Automation Expert

With over 15 years of industry experience, we serve more than 100 companies worldwide, backed by mature and reliable technology.

Cost Optimization

By upgrading to automation, customers can reduce labor costs by over 20% and achieve a high return on investment.

BEIST not only manufactures return conveyors for edge banders but also employs professional software engineers, who can design a complementary automation system based on your factory and manufacturing requirements. With over 30 professional mechanical engineers and technicians, we offer a one-stop solution for you.

BEIST's intelligent equipment has been exported to over 20 countries and regions, including Southeast Asia, Europe, and North America, providing automation solutions for the furniture, building materials, electronics, and automobile industries. Going forward, we will continue to advance technological innovation and deliver more efficient, intelligent non-standard automation equipment to our customers.